上海京蝶阀门制造有限公司自企业成立以来,就一直潜心致力于明杆闸阀、三通球阀、不锈钢蝶阀的专业研究、开发和生产,同时不断吸取国内外技术,公司阀门品质齐全。上海京蝶阀门制造有限公司以严格的质量管理,诚实信用的精神与优良的售后服务,赢得广大用户的信赖。我们一直秉承“用心制造、崇尚品质、不断创新、一切为了客户”的企业原则,不断提高管理水平和产品质量,进一步开扣国内市场,使客户以较短的时间和合理的价格,得到优良的产品和服务。我们竭诚欢迎新老客户光临惠顾,携手奋进,共展宏图。

产品详情 产品详情 |

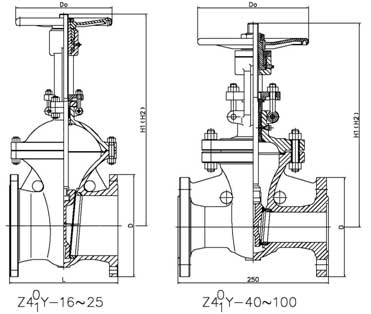

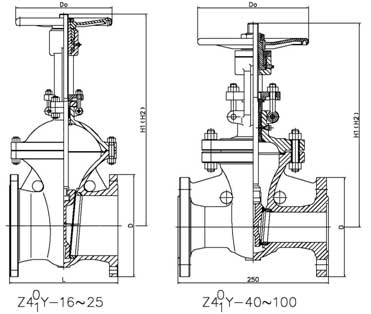

| 耐热钢楔式闸阀

闸阀是*常用的截断阀,主要用来接通或截断管路中的介质,不适用于调节介质流量。闸阀适用的压力、温度及口径范围很大,尤其适用于中、大口径的管道。

闸阀的主要优点:

(1)流体阻力小。闸阀闸体内部介质通道是直通的,介质流经闸阀时不改变其流动方向,因而流动阻力较小。

(2)启闭较省力。启闭时闸板运动方向与介质流动方向相垂直。与截止阀相比,闸阀的启闭较为省力。

(3)介质流动方向一般不受限制。介质可从闸阀两侧任意方向流过,均能达到接通或截断的目的。便于安装,适用于介质的流动方向可能改变的管路中。

主要零件材料及性能规范 | 主要零部件 | 阀体、阀盖、闸板 | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti 0Cr18Ni12Mo2Ti | ZG2Cr5Mo | | 阀杆 | 1Cr13 | 1Cr18Ni9Ti | 20Cr1Mo1V1 | | 阀杆螺母 | ZguAL10Fe3/球墨铸铁 | | 填料 | 柔性石墨、石墨石棉盘根 | | 主要 参数 | 适用介质 | 蒸汽、油品、水等 | 硝酸类 | 醋酸类 | 蒸汽、油品、水等 | | 适用适用温度℃ | ≤425 | ≤200 | ≤200 | ≤425 | | 型号 | 公称 | | 主要结构尺寸(mm) | 阀体 材料 | 性能规范 | | 通径 DN(mm) | 压力 PN(MPa) | D | D0 | L | H1 | H2 | 适用温度℃ | 适用 介质 | | Z410Y-16I | 50 | 1.6 | 160 | 200 | 250 | 185 | 240 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | " | 65 | " | 180 | 200 | 270 | 240 | 20 | " | " | " | | " | 80 | " | 195 | 250 | 280 | 350 | 395 | " | " | " | | " | 100 | " | 215 | 250 | 300 | 370 | 480 | " | " | " | | " | 150 | " | 280 | 300 | 350 | 560 | 720 | " | " | " | | " | 200 | " | 335 | 350 | 400 | 735 | 955 | " | " | " | | " | 250 | " | 405 | 400 | 450 | 880 | 1150 | " | " | " | | " | 300 | " | 460 | 450 | 500 | 1050 | 1375 | " | " | " | | " | 350 | " | 520 | 500 | 550 | 1195 | 1565 | " | " | " | | " | 400 | " | 580 | 550 | 600 | 1335 | 1760 | " | " | " | | " | 500 | " | 705 | 600 | 700 | 1720 | 2270 | " | " | " | | " | 600 | " | 840 | 650 | 800 | 1830 | 2480 | " | " | " | | " | 700 | " | 910 | | 900 | | | " | " | " | | Z410Y-25I | 50 | 2.5 | 160 | 200 | 250 | 185 | 240 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | " | 65 | " | 180 | 200 | 270 | 240 | 320 | " | " | " | | " | 80 | " | 195 | 250 | 280 | 305 | 395 | " | " | " | | " | 100 | " | 230 | 250 | 300 | 370 | 480 | " | " | " | | " | 150 | " | 300 | 300 | 350 | 560 | 720 | " | " | " | | " | 200 | " | 360 | 360 | 400 | 735 | 955 | " | " | " | | " | 250 | " | 425 | 425 | 450 | 880 | 1160 | " | " | " | | " | 300 | " | 485 | 485 | 500 | 1080 | 1405 | " | " | " | | " | 350 | " | 550 | 550 | 550 | 1210 | 1580 | " | " | " | | " | 400 | " | 610 | 610 | 600 | 1345 | 1780 | " | " | " | | " | 500 | " | 730 | 730 | 700 | 1740 | 2290 | " | " | " | | " | 600 | " | 840 | 650 | 800 | 1850 | 2500 | " | " | " | | " | 700 | " | 955 | | 900 | | | " | " | " | | Z410Y-40I | 50 | 4.0 | 160 | 250 | 250 | 220 | 295 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | " | 65 | " | 180 | 250 | 280 | 290 | 365 | " | " | " | | " | 80 | " | 195 | 300 | 310 | 360 | 450 | " | " | " | | " | 100 | " | 230 | 300 | 350 | 450 | 570 | " | " | " | | " | 150 | " | 300 | 350 | 450 | 620 | 790 | " | " | " | | " | 200 | " | 375 | 400 | 550 | 830 | 1050 | " | " | " | | " | 250 | " | 445 | 450 | 650 | 950 | 1235 | " | " | " | | " | 300 | " | 510 | 500 | 750 | 1120 | 1450 | " | " | " | | " | 350 | " | 570 | 550 | 850 | 1560 | 1940 | " | " | " | | " | 400 | " | 655 | 600 | 950 | 1770 | 2200 | " | " | " | | " | 500 | " | 755 | 680 | 1050 | 1880 | | " | " | " | | Z410Y-64I | 50 | 6.4 | 175 | 300 | 250 | 240 | 320 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | " | 65 | " | 200 | 300 | 280 | 310 | 390 | " | " | " | | " | 80 | " | 210 | 350 | 310 | 380 | 470 | " | " | " | | " | 100 | " | 250 | 350 | 350 | 470 | 590 | " | " | " | | " | 150 | " | 340 | 400 | 450 | 640 | 810 | " | " | " | | " | 200 | " | 405 | 450 | 550 | 850 | 1070 | " | " | " | | " | 250 | " | 470 | 500 | 650 | 1000 | 1270 | " | " | " | | Z410Y-64I | 300 | 6.4 | 530 | 550 | 750 | 1210 | 1550 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | Z410Y-100I | 50 | 10.0 | 195 | 300 | 250 | 260 | 340 | ZGCr5Mo | ≤550 | 蒸汽、油品、水 | | " | 65 | " | 220 | 300 | 280 | 330 | 410 | " | " | " | | " | 80 | " | 230 | 350 | 310 | 400 | 490 | " | " | " | | " | 100 | " | 265 | 350 | 350 | 490 | 610 | " | " | " | | " | 150 | " | 350 | 400 | 450 | 660 | 830 | " | " | " | | " | 200 | " | 430 | 450 | 550 | 1100 | 1320 | " | " | " | | " | 250 | " | 500 | 500 | 650 | 1300 | 1580 | " | " | " | | " | 300 | " | 585 | 550 | 750 | 1480 | 1810 | " | " | " | 注:法兰尺寸标准按JB/T79-1994。 |

如需查询更多相关产品信息,欢迎访问上海京蝶阀门制造有限公司

www.shjdvalve.com